At the 2023 Polish Process Mining Day conference, our Senior Data Scientist Agnieszka Żuber showcased the utility of process mining, taking an underground coal mine as her case study. Discover how process mining can offer valuable insights to enhance operations in mining and beyond, across the entire heavy industry sector.

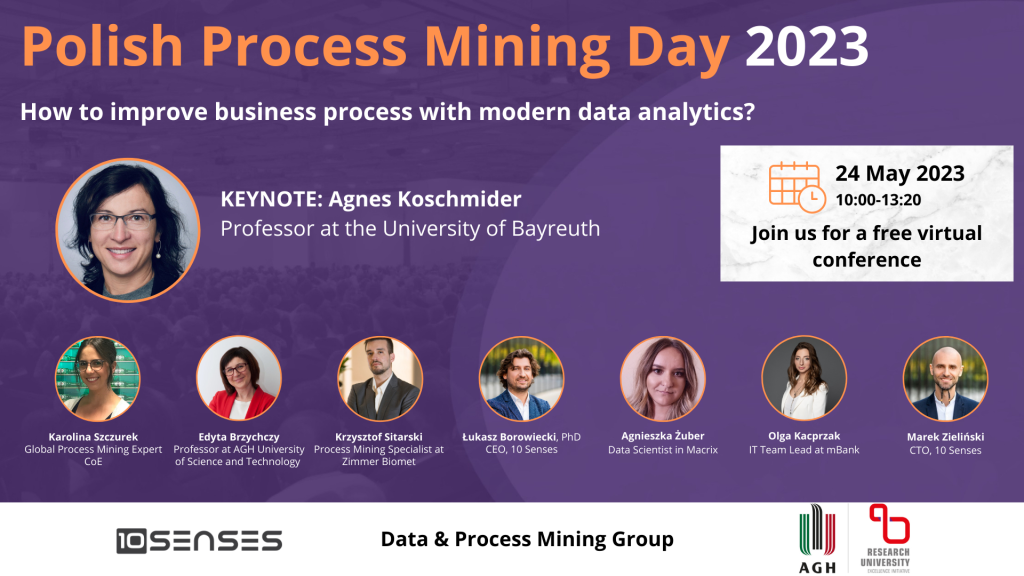

Over a week ago, on 24 May I had the pleasure to speak at the “Polish Process Mining Day 2023”, the third edition of the very well-known conferences in Poland fully dedicated to state-of-the-art process analytics. The conference is co-organized by 10 Senses and the Data & Process Mining Group from the AGH University of Science and Technology. The conference has become an annual tradition, where professionals and experts gather and share knowledge and process data in Poland.

Image source: Organizer / 10 Senses

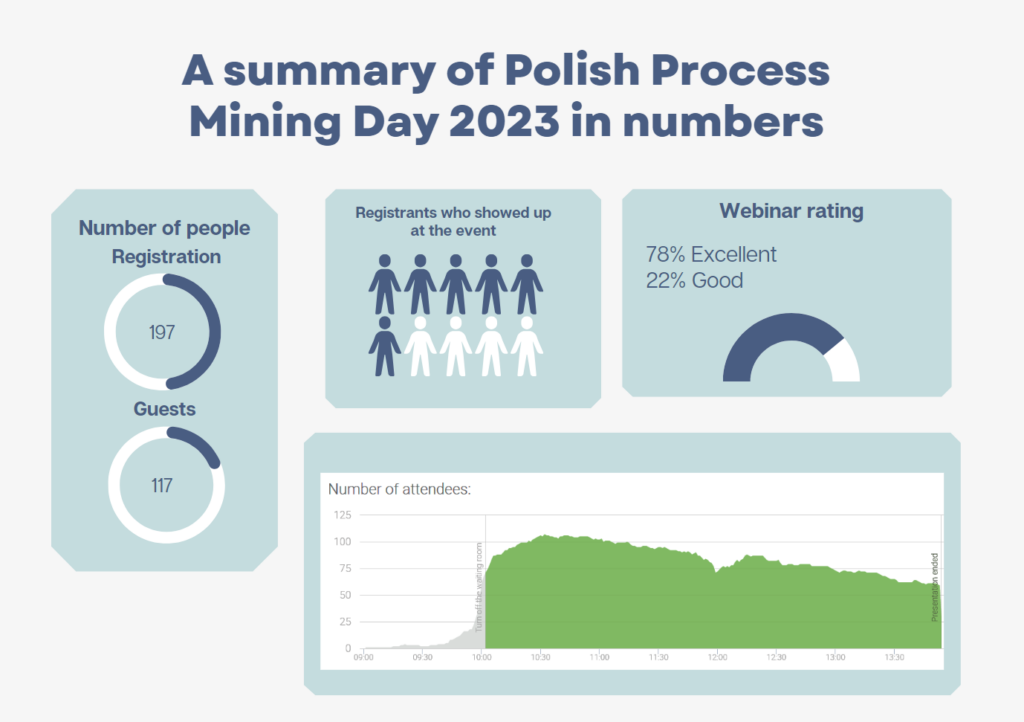

Image source: Agnieszka Żuber

The conference was divided into two sections and contained eight lectures led by industry process mining leaders:

Cutting-edge research:

Use cases from companies:

For my presentation, I talked about my work on the Ph.D. thesis titled “Analyzing Mining Process Based on Event Data,” which introduces fact-based insights and an analytic method for modeling and analyzing the longwall mining process using event logs. In addition, I demonstrated the application of process mining in heavy industry.

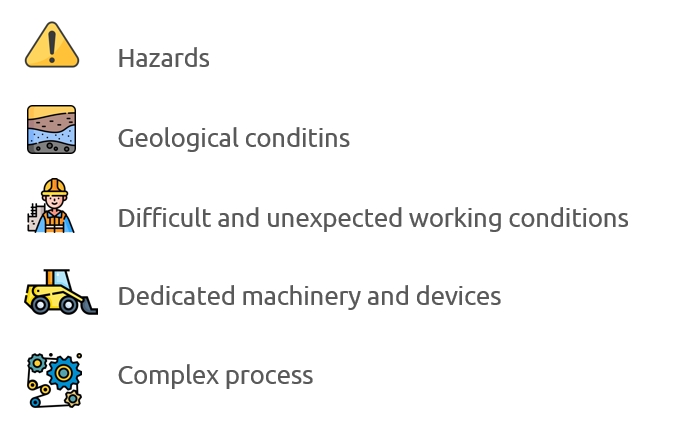

First, I introduced the specification of an underground coal mine and the main factors which have an impact on the environment.

Image source: Agnieszka Żuber

Longwall mining is a technique whereby coal is mined by sliced blocks (from 0.6 to 1.2 meters in thickness) usually 100 to 300 meters wide and 1,000 to 3,000 meters long. The process involves coal cutting along the width of the panel (longwall face length) to the depth of the intended slice (having the width of the longwall panel). Next, crushed coal is loaded onto a conveyor (Armoured Face Conveyor). The sequence of operations continues after the roof support (Powered Roof Supports) is propped at the front and the conveyor advances forward. The crushed coal is transported to the breaker feeder (Crusher) via a chain conveyor (Beam Stage Loader).

As the shearer moves across the coal seam, large hydraulic rams attached to the roof support the modules providing temporary support of the roof, progressively advancing the AFC which is then held in place while each support, in turn, is pulled to the new alignment. The working shearer moves in two directions: back (Along) and forth (Return) alongside the length of the longwall. The coal shearer is mounted on a conveyor operating underneath a series of self-advancing hydraulic roof supports. The steps described above define a common cutting method involving operations repeated in a specified sequence and cyclical implementation of operations (activities) in a longwall face.

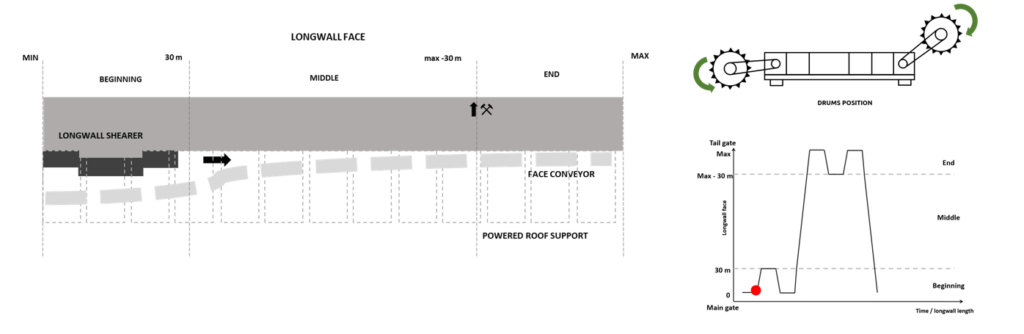

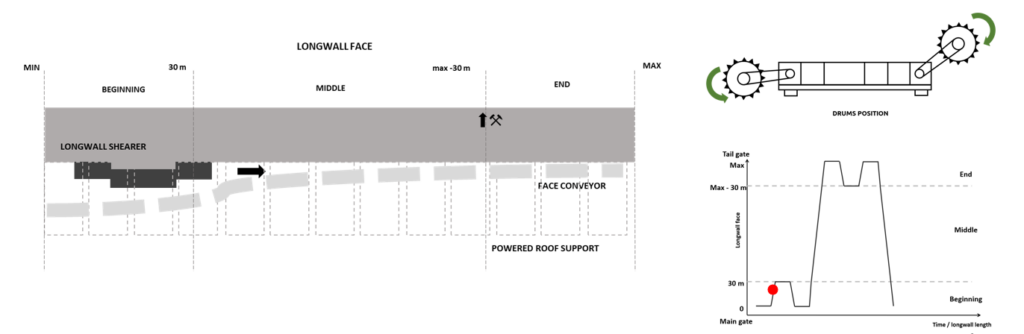

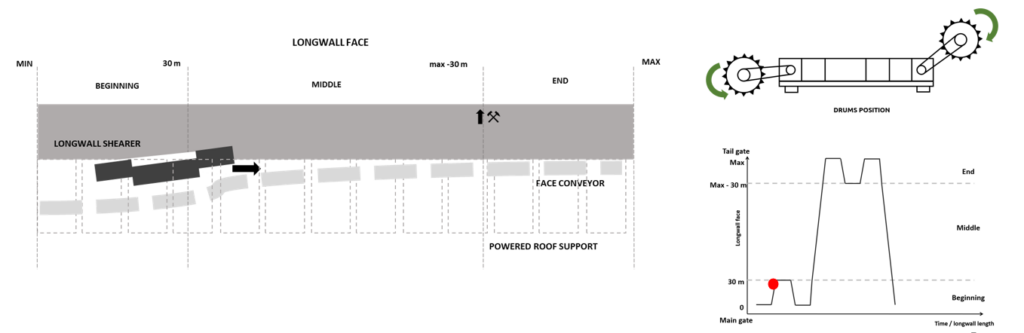

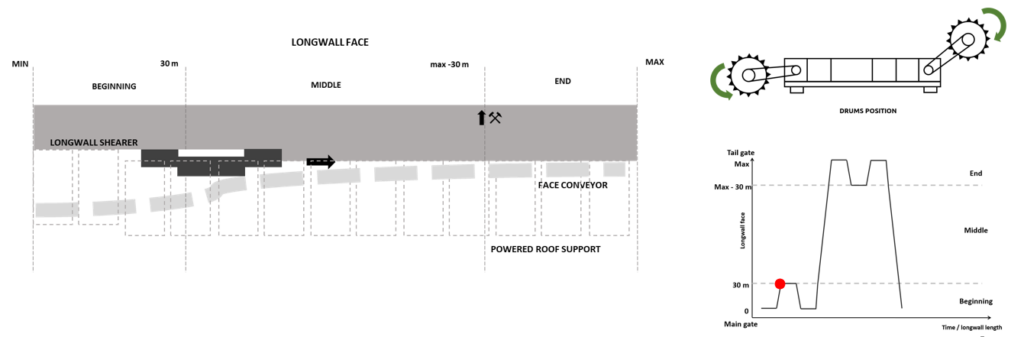

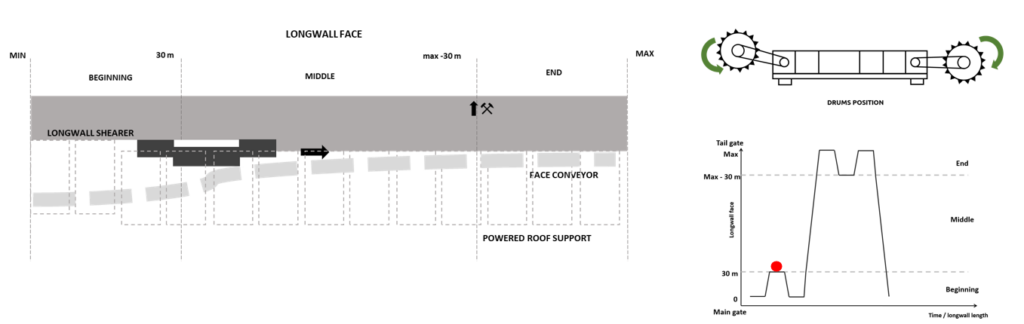

In the next part of my presentation, I tried in a very simple way to introduce the process that I was analyzing in my Ph.D. The shearer is the most important part of this process, it performs the process – cutting the coal. In the below pictures, I present a general longwall scheme with the shearer’s arms position. Graph showing the position of the shearer in the longwall over time. Sherer’s movement is presented as a token in this plot. The longwall mining process contains 7 main stages.

Image source: Agnieszka Żuber

The mining industry is facing a number of challenges that are forcing the adoption of new technologies and continuous process improvement in many aspects. By taking advantage of developments in virtualization and computerization in mining, it is possible to monitor virtually all events and activities occurring in mining processes.

Advances in sensor technology Industrial Internet of Things – (IoT) and enhanced capabilities of computer hardware and software are increasingly used in underground coal mines, however along with the increased amount of collected data, there is a growing need to develop tools for its efficient processing and analysis. The primary data analytic approaches used in underground mining are data-oriented and not process-centric; they focus on knowledge discovery from data through the use of traditional and advanced analytic techniques such as Machine Learning (ML), data mining, and statistics. However, process improvement activities require a process-oriented analysis of the available data. Process Mining techniques provide new opportunities for knowledge discovery from data about processes. However, process discovery from industrial raw sensor data has to meet several requirements imposed by traditional PM techniques, which in such cases, may not be an easy task.

In terms of advanced data analytics in the Mining Industry, I wanted to emphasize that the application Internet of Things and Industry 4.0 in the mining industry now become a standard. Modern monitoring and diagnostic systems applied in an underground mine provide full access to information integrated in one place from a whole spectrum of sensors, however… usage of new, available sensor data in a process improvement currently is insufficient. Especially if we consider that data analysis in the mining industry relies mostly on data-oriented techniques and does not focus on process analysis. It provides only “stationary” information about the process.

In my thesis, I wanted to deliver valuable information about the process execution, deviations, and anomalies. That is why in looking for new analytic possibilities for industrial data, Process Mining should be taken into consideration as a process-oriented approach to data analysis.

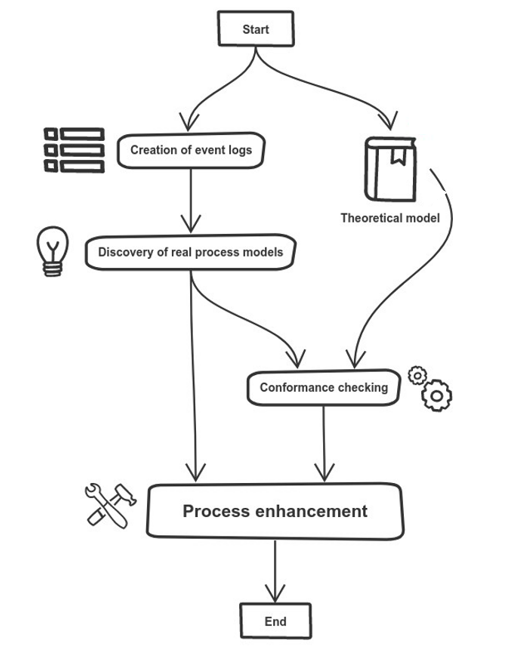

In my Ph.D. thesis, I proposed a method of analysis of row sensor data that contained 4 steps:

Image source: Agnieszka Żuber

1. The first phase involves the creation of event logs from raw sensor data for longwall monitoring systems. This task was very demanding. Currently, in IT systems there is no information about activities and case id. I had to develop a method to detect this. The problem with data quality was very burdensome and required many cleaning activities, in total they greatly affect the result of the analysis.

2. The second step involves the modeling and analysis of the process based on the created events log, leading to the discovery of real process models. At this stage, it turned out that some of the discovered states are very detailed and difficult to interpret. They had to be additionally generalized, which was another challenge in the analysis.

3. The next step involves conformance checking by comparing created event logs with the theoretical model to identify deviations. Due to the excessive detail of the created event logs, only a specific event log could be used for conformance checking.

4. The last step provides suggestions for process improvement using the discovered model and process enhancement techniques. Additional information about the operation of the system, i.e. geological information or information about the staff, was not available at the time of my analyses.

Image source: Agnieszka Żuber

This method looks fairly simple but each step was done iteratively, and many approaches were evaluated.

In the last part of my presentation, I showed the most interesting results of my work:

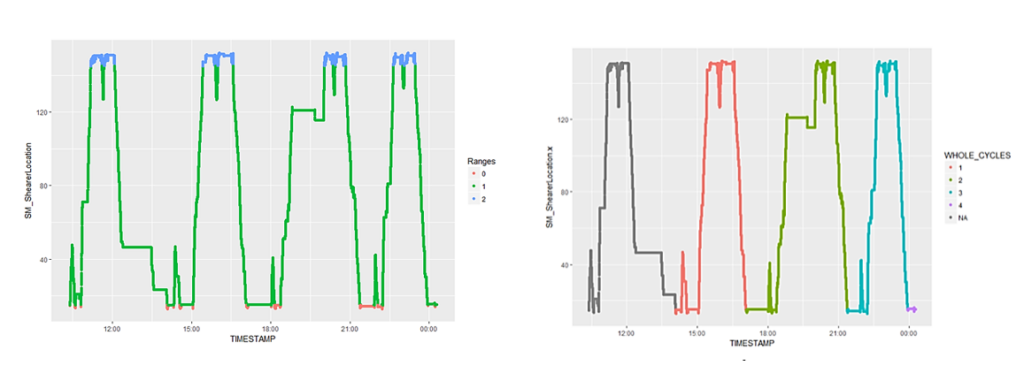

1. Case identification

Image source: Agnieszka Żuber

For work cycles (case id) identification was applied the heuristic approach involved several steps and mainly relied on the analysis of the attributes indicating the location and driving direction.

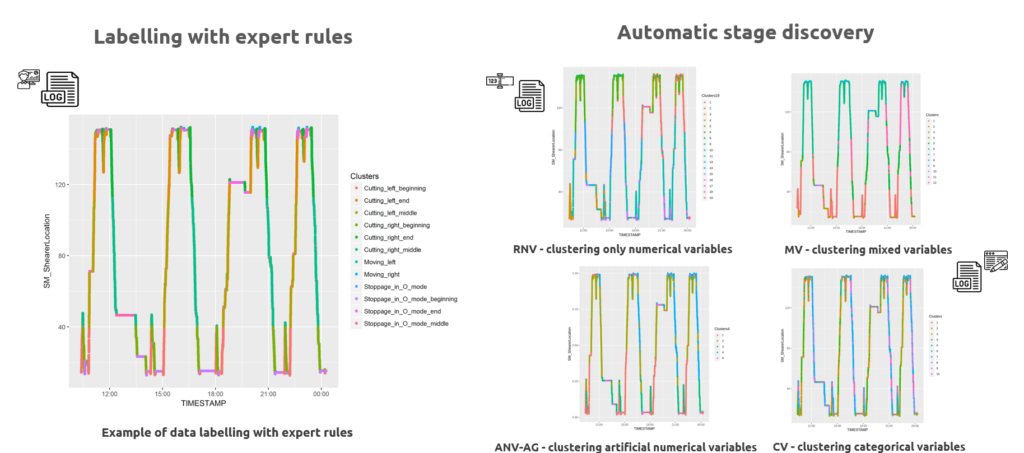

2. Stage identification

For stage identification, we apply two approaches:

As I mentioned at the beginning of the text, each clustering approach included several iterations and many recalculations.

Image source: Agnieszka Żuber

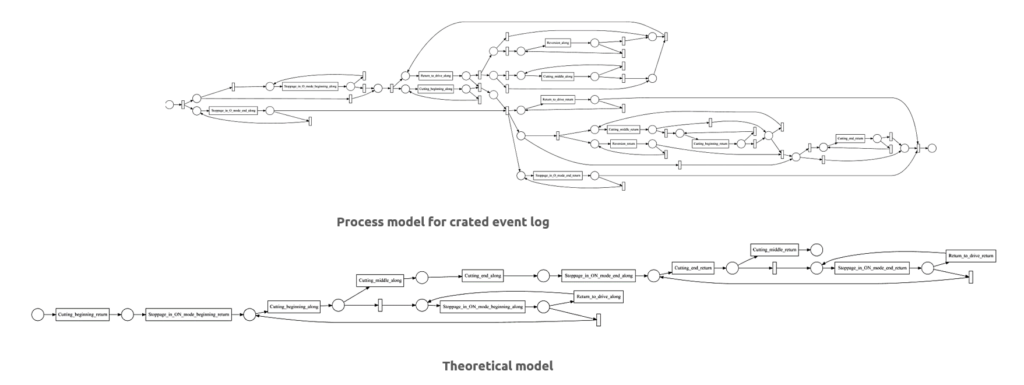

3. Model discovery

Example of discovered real model based on expert rules compared with the theoretical model. The real model is much more complex and contains stages that do not appear in the theoretical model. Based on the actual event log and theoretical model, we can analyze all kinds of deviations which was the next step of my work in my Ph.D. thesis.

Image source: Agnieszka Żuber

I am very happy to have been invited to this conference. From a scientific point of view, it was a great event! Exchange of knowledge and experience in both scientific and business cases. I was very impressed by the scope of the meeting. It was a great opportunity to hear about the experience and results of other companies in terms of Process Mining. I secretly hope that next year, as Macrix, we will show our experience and boast of our achievements in the Process Mining topic.

Agnieszka Żuber, Senior Data Scientist