As one of only a few companies worldwide, BSS Bohnenberg GmbH plans and carries out complete intralogistics solutions as a general contractor – tailor-made and turnkey, with all services from one provider. For years now, Macrix has been a partner of BSS in the development and implementation of software solutions.

Development of a Warehouse Management System

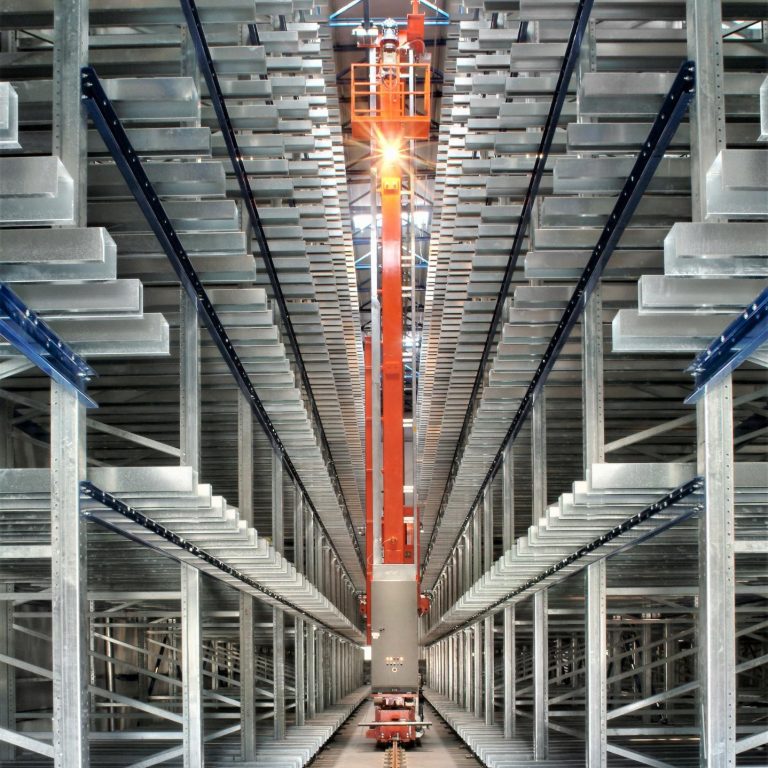

Automated storage

and retrieval

Efficient

production

Process

A team consisting of the end customer’s employees, BSS engineers and Macrix software developers successfully modernized the warehouse in less than six months. Due to production specifications, only a few days were available for commissioning. Nevertheless, the modernized warehouse could be integrated into the production processes seamlessly and almost error-free.

The ProconTEL framework developed by Macrix, which is tailored to the specific requirements of distributed applications, served as the basis for the WMS.

Our software developers have developed a functional, intuitive and fully scalable user interface for the system that optimally supports the work of the order pickers. The built-in control functions minimize the risk of errors and guarantee efficient order picking.

- Design, bid, build contracts

- Planning and scheduling

- Design-build contracts

- Construction manager

- Contract administrator

- Consulting engineer

Client Testimonials

Michael Effertz

PDV Department Head

Maximilian Schnitzler

Managing Director

For several years now, a multi-member team of Macrix GmbH has been a competent and reliable partner in software development and commissioning for the digitalization of the opencast mine.

RN-Vision offers motorsports customers around the world a professional, intuitive and user-friendly analysis tool. With Macrix, we have an experienced partner at our side who supports us in both hardware production and software design. Together we design innovative products and solutions for our customers.